- Posts: 2181

- Thank you received: 1685

Bugs: Recent Topics Paging, Uploading Images & Preview (11 Dec 2020)

Recent Topics paging, uploading images and preview bugs require a patch which has not yet been released.

Making a Crokinole board

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

Since I can get four boards out of a piece of plywood, why not make four? I'll start with one and finish it to get the process down and make any mistakes and then try to assembly line the other three.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- Jackwraith

-

- Away

- Ninja

-

- Maim! Kill! Burn!

- Posts: 4375

- Thank you received: 5710

Please Log in or Create an account to join the conversation.

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

- Posts: 2181

- Thank you received: 1685

First thing to do was make some circle jigs for my routers, to both cut out the deck and to engrave the lines. I didn't want to use my big, heavy plunge router for the lines, and didn't want to tax the little router too much from going through a lot of 1/2” plywood, so I made two. I grabbed some 1/4” MDF I had around and made one with a 13” radius for the big router, and a smaller one with radii at 4”, 8”, and 12” for the lines. I’m using a binding post (which is like a sleeve a machine screw can screw into) for the pivot point. I can drill a hole in the center of the deck and just pop the jig post in the hole.

I almost screwed up and drilled the hole for the jig before realizing that if I did that, I wouldn’t be able to use a forstner bit for the 20 hole later, since the existing jig hole would be too big to center the forstner bit in it. My solution was to cut out a very shallow portion of the 20 hole (so I could come back later and finish it), and then drill the jig hole in the center.

There was a little play in my jig and I got a little wiggle in a small section of the outer line. I’ll have to see if I can figure out some fix later, or just not worry about it.

I will definitely have to replace these MDF jigs with acrylic ones to make them more rigid.

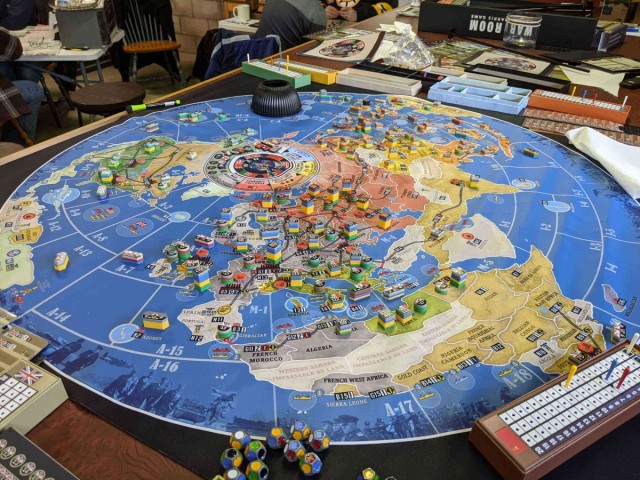

Deck with the lines v-grooved:

I don’t have a resaw blade for my bandsaw so I am waiting on one to arrive before I can start cutting out the strips for the outside wall.

Even the basic stuff I’ve done so far has really taught me to tone down my tendency to try to make everything pixel perfect and relax.

Please Log in or Create an account to join the conversation.

- ChristopherMD

-

- Away

- Road Warrior

-

- Posts: 5241

- Thank you received: 3797

Please Log in or Create an account to join the conversation.

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

- Posts: 2181

- Thank you received: 1685

Please Log in or Create an account to join the conversation.

- Sagrilarus

-

- Offline

- D20

-

- Pull the Goalie

- Posts: 8740

- Thank you received: 7357

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

- Posts: 2181

- Thank you received: 1685

Please Log in or Create an account to join the conversation.

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

- Posts: 2181

- Thank you received: 1685

On a side note, I found out when gluing the edges together, that the factory edges aren't necessarily 90 degree cuts, so I'll need to trim them myself one future boards.

Up next is ironing on the veneer to the deck edge and sanding everything. I also got the resawing band saw blade and need to try to get that set up properly.

Please Log in or Create an account to join the conversation.

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

- Posts: 2181

- Thank you received: 1685

I then sanded the deck and the base. It was at this point, particularly on the base, that I found out that the birch veneer of the plywood is SUPER thin and quite easy to accidentally sand through. And the layer below it (or maybe the glue?) is orange so it is very obvious on the glued up edges of the base where I sanded them flush. I wanted to stain the gutters, but I think I’ll just paint them to hide the ugly coloring.

Regarding the plywood, I bought the shop grade version because it was nearly half the price and the flaw on one side was minor. I assume the regular version has the same thickness of veneer. I should check around to a few other places and see if they carry hardwood plywood with thicker veneers. Or maybe I just need to get better at gluing pieces together flush.

Please Log in or Create an account to join the conversation.

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

- Posts: 2181

- Thank you received: 1685

Please Log in or Create an account to join the conversation.

- hotseatgames

-

- Away

- D12

-

- Posts: 7185

- Thank you received: 6313

Please Log in or Create an account to join the conversation.

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

- Posts: 2181

- Thank you received: 1685

I got my band saw set up and cut the 2 rail pieces. I soaked them in water for an hour and then clamped them up to let dry.

Once they're dry, I'll attach them to the base. This seems like the most complicated part of the process, so we'll see how it goes.

Please Log in or Create an account to join the conversation.

- Disgustipater

-

Topic Author

Topic Author

- Offline

- D8

-

- Dapper Deep One

- Posts: 2181

- Thank you received: 1685

I made full circumference rails instead of two halves, so I had to rush everything before the glue dried, and not always successfully. I didn't set up enough space to hold the thing with all the clamps on it, so I'm surprised I didn't drop it on the floor. Other than needing to get more clamps, next time I will only put a little glue on at a time as I clamp it around the base instead of putting the glue on all the way around right off the bat. I will also dry-fit it with clamps to cut the ends flush to length instead of when I was trying to glue it because it took way too long.

Please Log in or Create an account to join the conversation.

Games

Games

How to resolve AdBlock issue?

How to resolve AdBlock issue?